Hot chamber die casting is one of the two main techniques in the

manufacturing process of die casting. This section will primarily

discuss the specific details of the hot chamber process and contrast the differences between

hot chamber die casting and cold chamber die

casting, which is the other branch of die casting manufacture.

Hot Chamber Process

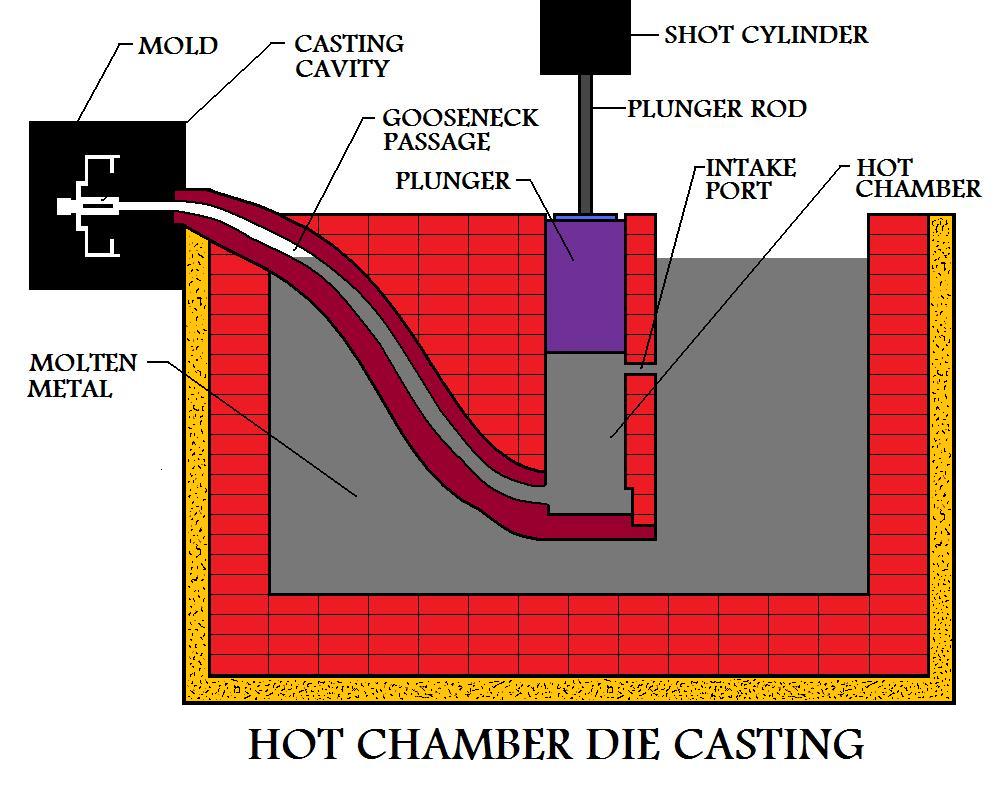

A similar characteristic of either die casting process is the use of high pressure to force molten metal through a mold called a die. Many of the superior qualities of castings manufactured by die casting, (such as great surface detail), can be attributed to the use of pressure to ensure the flow of metal through the die. In hot chamber die casting manufacture, the supply of molten metal is attached to the die casting machine and is an integral part of the casting apparatus for this manufacturing operation.

|

The shot cylinder provides the power for the injection stroke. It is located above the supply of molten metal. The plunger rod goes from the shot cylinder down to the plunger, which is in contact with the molten material. At the start of a casting cycle, the plunger is at the top of a chamber (the hot-chamber). Intake ports allow this chamber to fill with liquid metal.

As the cycle begins, the power cylinder forces the plunger downward. The plunger travels past the ports, cutting off the flow of liquid metal to the hot chamber. Now there should be the correct amount of molten material in the chamber for the "shot" that will be used to fill the mold and produce the casting.

At this point the plunger travels further downward, forcing the molten metal into the die. The pressure exerted on the liquid metal to fill the die in hot chamber die casting manufacture usually varies from about 700psi to 5000psi (5MPa to 35 MPa). The pressure is held long enough for the casting to solidify.

In preparation for the next cycle of casting manufacture, the plunger travels back upward in the hot chamber exposing the intake ports again and allowing the chamber to refill with molten material.

For more extensive details on the setup of the mold, the die casting process, or the properties and considerations of manufacturing by die casting see die casting for the basics of the process.

Hot chamber die casting has the advantage of a very high rate of productivity. During industrial manufacture by this process one of the disadvantages is that the setup requires that critical parts of the mechanical apparatus, (such as the plunger), must be continuously submersed in molten material. Continuous submersion in a high enough temperature material will cause thermal related damage to these components rendering them inoperative. For this reason, usually only lower melting point alloys of lead, tin, and zinc are used to manufacture metal castings with the hot chamber die casting process

The benchtop environmental chamber also call the small environmental chamber, it can test the temperature, thermal, etc, DGBell is the benchtop environmental chamber manufacturer. To know more information visit Small benchtop environmental chamber

ReplyDelete