The functions of the condenser are to desuperheat the high pressure gas, condense

it and also sub-cool the liquid.

Heat from the hot refrigerant gas is rejected in the condenser to the condensing

medium-air or water. Air and water are chosen because they are naturally

available. Their normal temperature range is satisfactory for condensing

refrigerants.

Like the evaporator, the condenser is also heat exchange equipment

it and also sub-cool the liquid.

Heat from the hot refrigerant gas is rejected in the condenser to the condensing

medium-air or water. Air and water are chosen because they are naturally

available. Their normal temperature range is satisfactory for condensing

refrigerants.

Like the evaporator, the condenser is also heat exchange equipment

Other Topics

IC engine, Method

of Ignition, mechanical

Engineering, English books,Photoshop

tutorials,Harry

potter,Best

100 english books,IC

engine,Metal

Casting,Mechnical

Previous Years Gate Question Papers ,Mechanical-old-question-paper,Milling

Quiz,Forging

Quiz,Cold

Extrusion,Hot

Extrusion,CLutch,Wet Clutch,Introduction

to Flywheel,Flywheel:

FACTOR,

Governors ,Thermal

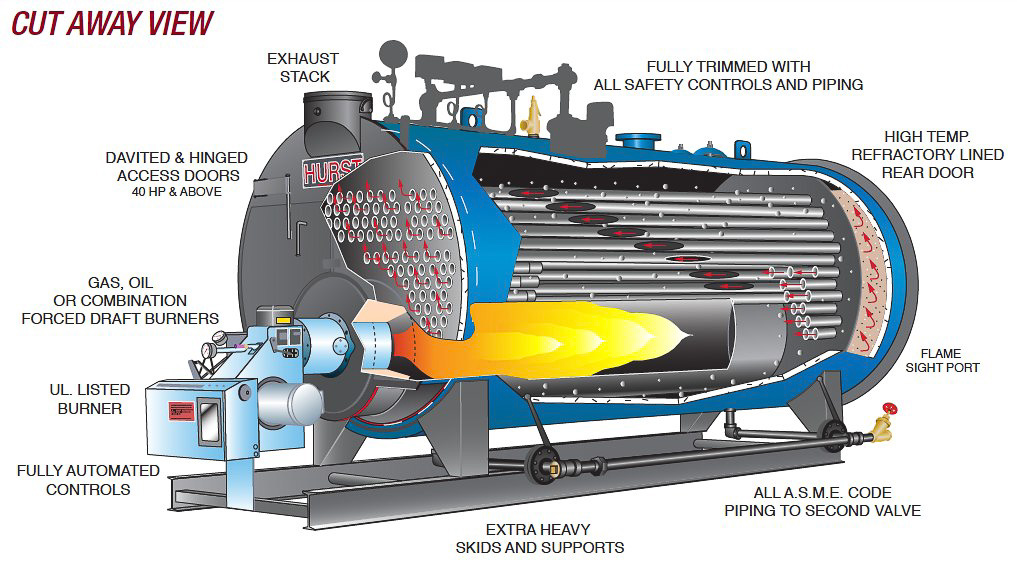

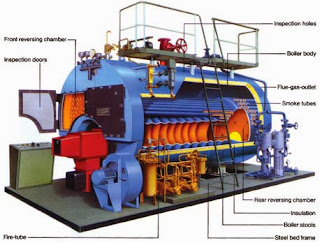

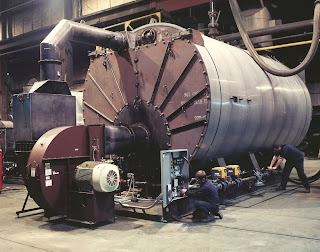

Power Plant,Pulverizer,Boiler,Fire

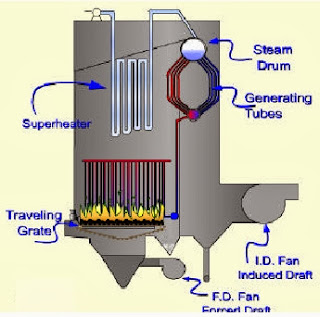

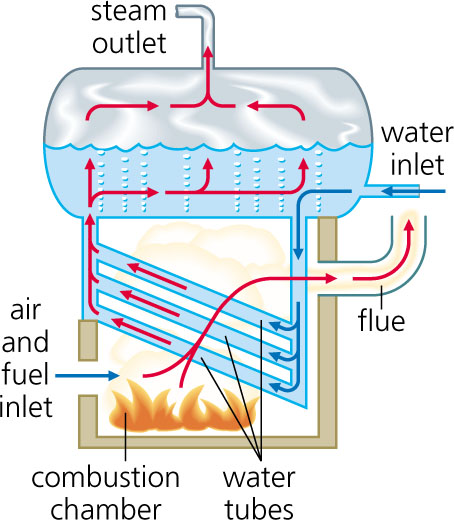

Tube Boiler,Water

Tube Boiler,Packaged

Boiler,Superheater,Condenser