Continuous casting, also referred to as strand casting, is

a process used in manufacturing industry to cast a continuous length of metal. Molten

metal is cast through a mold, the casting takes the two dimensional profile of the mold

but its length is indeterminate. The casting will keep traveling downward, its length

increasing with time. New molten metal is constantly supplied to the mold, at exactly

the correct rate, to keep up with the solidifying casting. Industrial manufacture of

continuous castings is a very precisely calculated operation. Continuous casting can

produce long strands from aluminum and copper, also the process has been developed

for the production of steel.

The Process

Molten metal, from some nearby source, is poured into a

tundish.

A tundish is a container that is located above the mold, it holds the liquid metal

for the casting. This particular casting operation uses the force of gravity to fill the

mold and to help move along the continuous metal casting. The tundish is where the

operation begins and is thus located high above ground level, as much as

eighty or ninety feet. As can be seen, the continuous casting operation may require

a lot of space.

It is the job of the tundish to keep the mold filled to the right level throughout

the manufacturing operation. Since the metal casting is constantly moving through the

mold, the tundish must always be supplying the mold with more molten metal to

compensate.

The supplying of metal to the mold is not only going on throughout the entire

manufacturing operation, it must be carried out with accuracy. A control system

is employed to assist with this task. Basically the system can sense what the level of

molten metal is, knows what the level should be, and can control the pouring of the

metal from the tundish to ensure the smooth flow of the casting process.

Although the tundish can typically hold several thousand pounds of metal, it

too must be constantly supplied from the source of molten material.

The tundish also serves as the place where slag and impurities are removed from

the melt. The high melting point and reactive nature, at high temperatures, has always made

steel a difficult material to cast. When a manufacturing operation is continuously casting

steel, the reactivity of the molten steel to the environment needs to be controlled. For this

purpose, the mold entrance may be filled with an inert gas such as argon. The inert gas

will push away any other gases, such as oxygen, that may react with the metal. There is

no need to worry about the inert gas reacting with a molten metal melt, since inert gases

do not react with anything at all.

The metal casting moves quickly through the mold, in the continuous manufacture of the

metal part. The casting does not have time to solidify completely in the mold. As can be

remembered from our discussion on solidification, a metal casting will first solidify from the

mold wall, or outside of the casting, then solidification will progress inward. The mold in

the continuous casting process is water cooled, this helps speed up the solidification of the

metal casting. As stated earlier, the continuous casting does not completely harden in the

mold. It does, however, spend enough time in the water cooled mold to develop a protective

solidified skin of an adequate thickness on the outside.

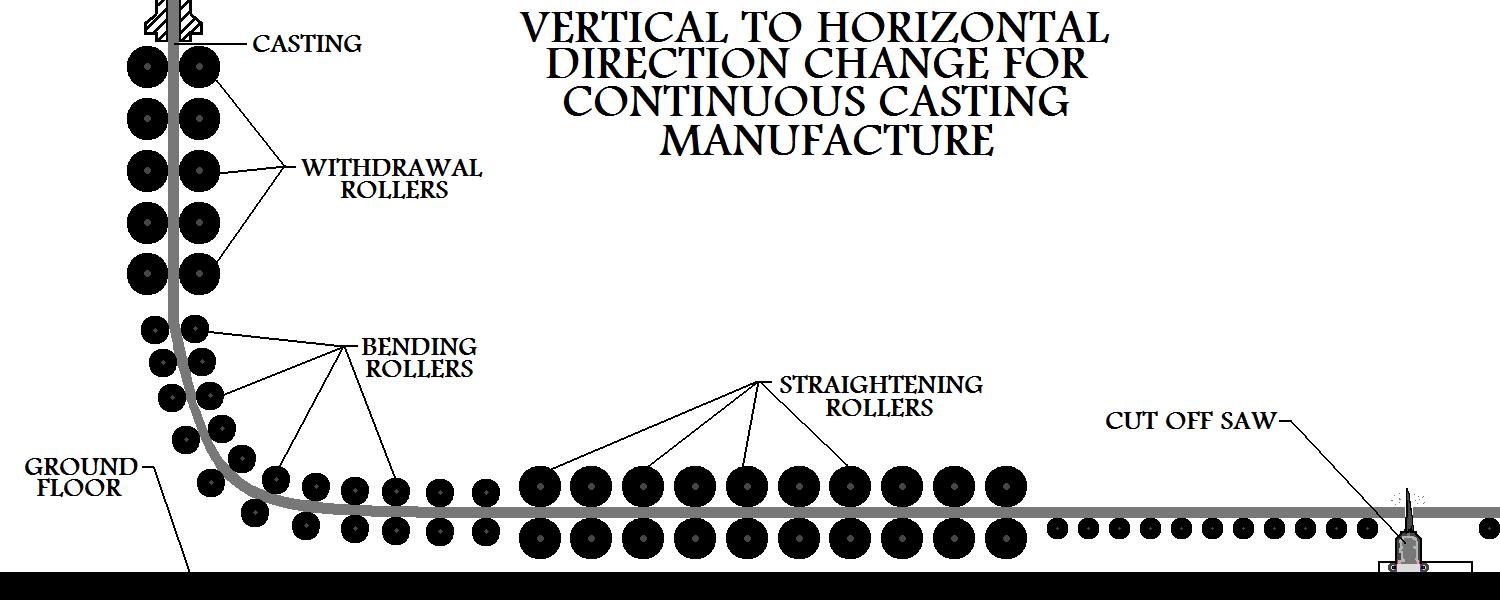

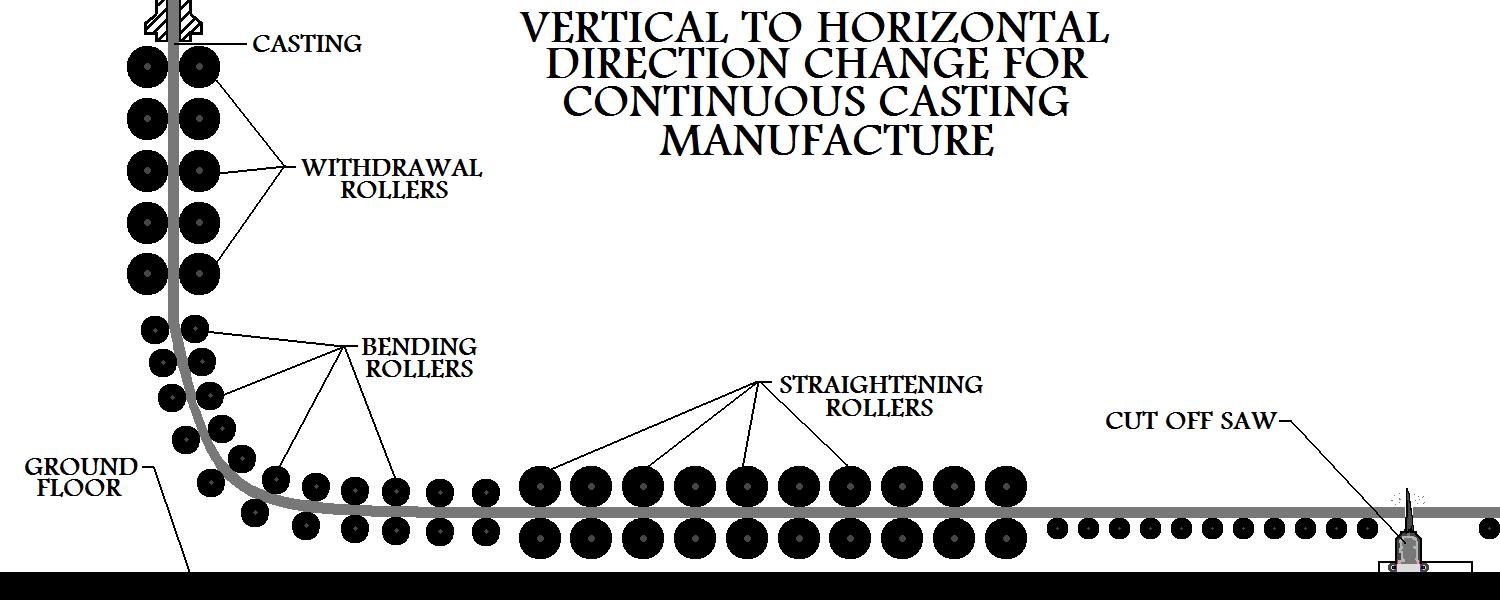

The long metal strand is moved along at a constant rate, by way of rollers. The rollers

help guide the strand and assist in the smooth flow of the metal casting out of the mold and along

its given path. A group of special rollers may be used to bend the strand to a 90 degree angle.

Then another set will be used to straighten it, once it is at that angle. Commonly used in

manufacturing industry, this process will change the direction of flow of the metal strand from

vertical to horizontal.

|

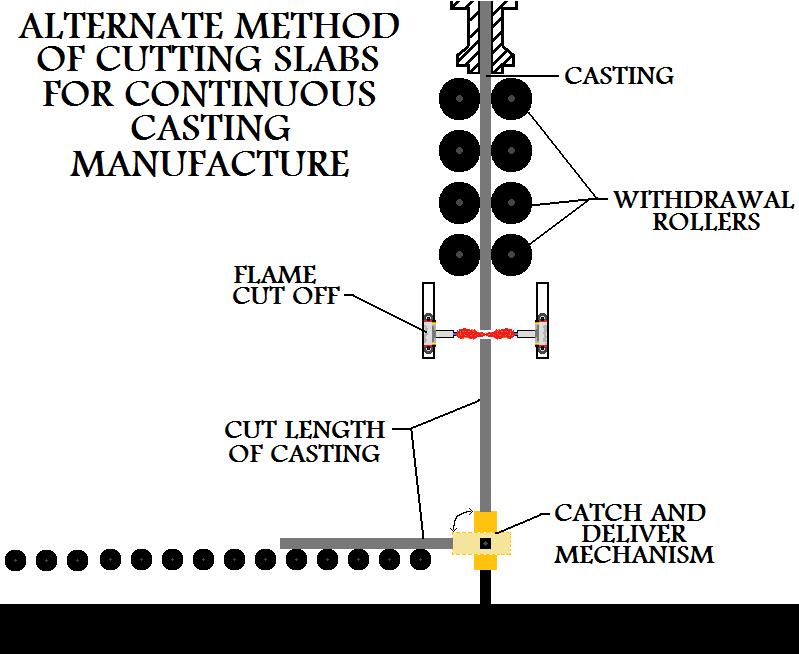

The continuous casting can now travel horizontally as far as necessary. The cutting

device, in manufacturing industry, is typically a torch or a saw. Since the metal casting does not

stop moving, the cutting device must move with the metal casting, at the same speed, as it does

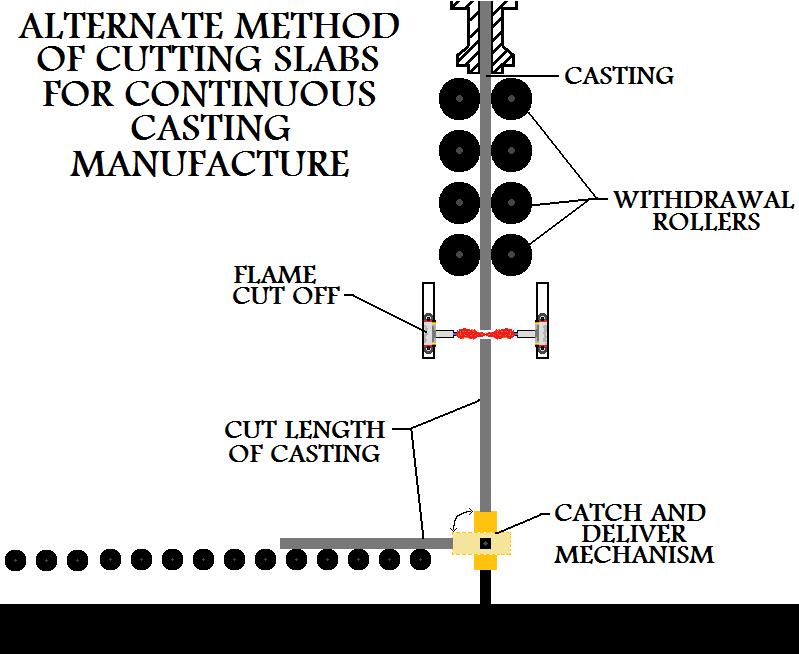

its cutting. There is another commonly used setup for cutting lengths of metal casting strand from

a continuous casting operation. This particular manufacturing setup eliminates

the need for bending and straightening rollers. It does, however, limit the length of

metal casting strand that may be produced, based in a large part on the height of the casting

floor where the mold is located.

|

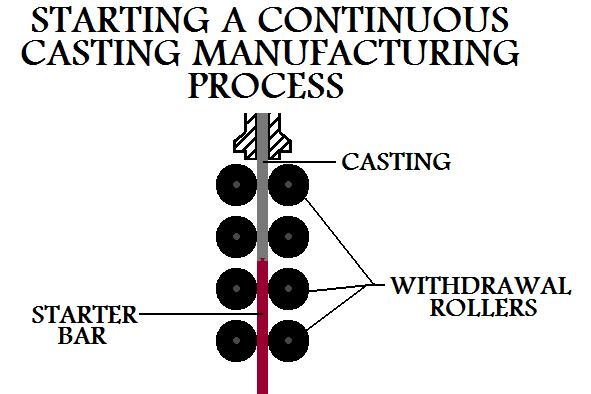

There needs to be an initial setup for a continuous casting operation, since you can not

just pour molten metal through an empty system to start off the process. To begin

continuous casting manufacture, a starter bar is placed at the bottom of the mold. Molten

material for the metal casting is poured into the mold and solidifies to the bar. The bar gives the

rollers something to grab onto initially. The rollers pull the bar, which pulls along the

continuous casting.

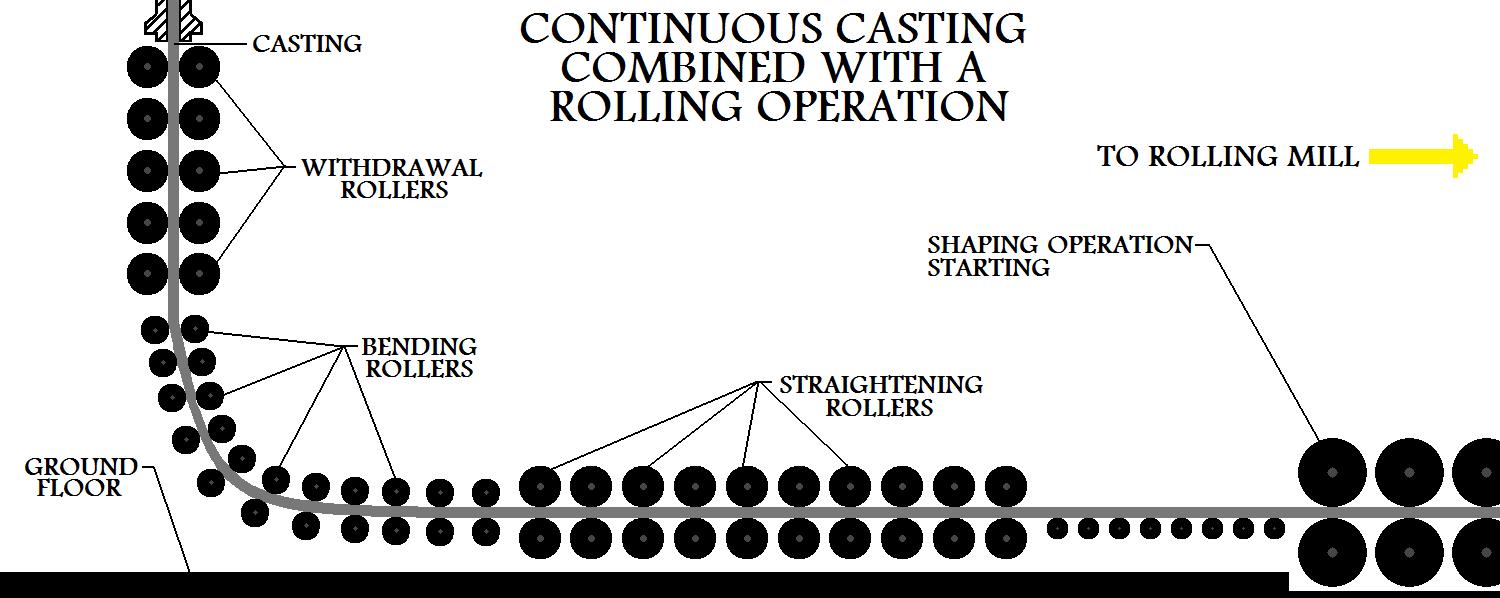

In the manufacture of a product, often two or more different kinds of operations may

need to be performed. Such as a metal casting operation followed by a metal forming operation. In

modern commercial industry, the continuous casting process can be integrated with metal rolling.

Do not confuse the

rolling operation with the

rolls used to guide the casting.

The rolling operation is a forming process and it will change the metal it processes.

Rolling of the metal strand, is the second manufacturing process and it must be performed

after the casting operation. Continuous casting is very convenient in that the rolling mill can be

fed directly from the continuously cast metal casting strand. The metal strand can be rolled

directly into a given cross sectional shape such as an I beam. The rate of the rolling operation

is synchronized with the speed that the continuous metal casting is produced and thus the

two operations are combined as one.

Properties And Considerations Of Manufacturing

By Continuous Casting

- Continuous casting manufacture is different from other metal casting processes, particularly

in the timing of the process. In other casting operations, the different steps to the process

such as the ladling of metal, pouring, solidification, and casting removal all take place

one at a time in a sequential order. In continuous casting manufacture, these steps are all

occurring constantly and at the same time.

- This process is used in commercial manufacture as a replacement to the

traditional process of casting ingots.

- Piping, a common problem in ingot manufacture, is eliminated with the continuous

casting process.

- Structural and chemical variations in the metal of the casting, often present in

ingots, have been eliminated. When manufacturing with the continuous metal casting process,

the casting's material will possess uniform properties.

- When employing continuous metal casting manufacture, the castings will solidify at

10 times the rate that a casting solidifies during ingot production.

- With less loss of material, cost reduction, higher productivity rate, and superior

quality of castings, continuous casting manufacture is often the choice over ingot

production.

- A continuous casting manufacturing process will take considerable resources and

planning to initiate, it will be employed in only very serious industrial operations.

Other Topics

IC engine,

Air

Standard Cycles,

Method

of Ignition,

Gear Types,

mechanical

Engineering,

Gears,

spur gears,

Worm gears,

English books,

Photoshop

tutorials,

Physics files,

Thamizh,

Manufacturing,

Gears pdf,

Computer

science,

Harry

potter,

Best

100 english books,

Face Gears,

IC

engine,

Metal

Casting,

Sand

casting,

SAND

Casting Quiz,

Casting

patterns quiz,

Sand

Casting Process,

Patterns,

Mechnical

Previous Years Gate Question Papers ,

Mechanical-old-question-paper,

Core

and Core Box,

Shell

Moulding,

Permanent

mold casting,

Investment

Casting,

Die

Casting,

Centrifugal

Casting,

Workshop

Technology Quiz,

Milling

Quiz,

Metal

Quiz,

Mechanical

Process Quiz,

Chemically

Bonded Molding Systems,

Unbonded

Sand Processes,

Green

Sand Molding,

Gases

Iin Metal Casting,

Plaster

Mold Casting,

Ceramic

Mold Casting,

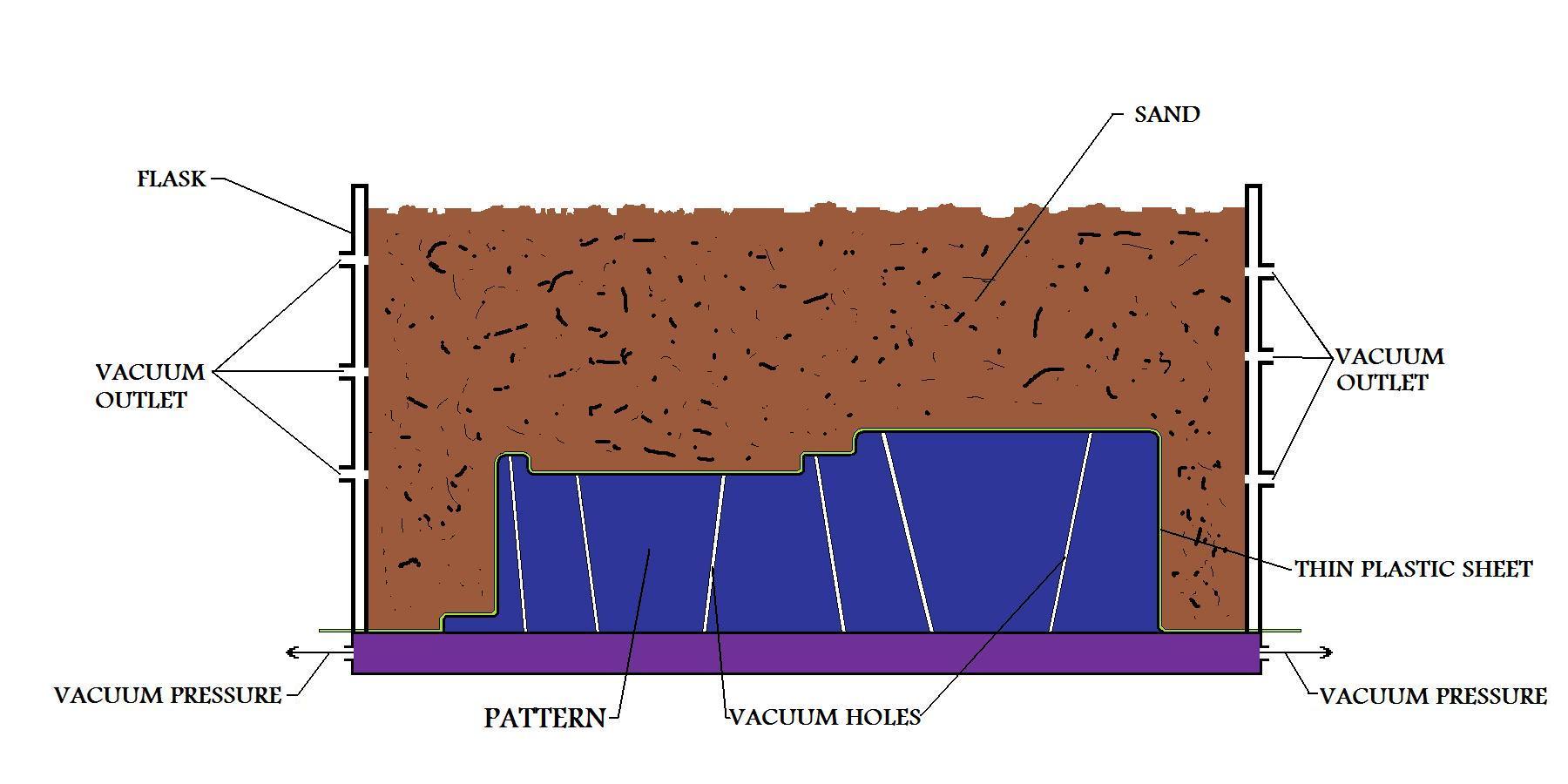

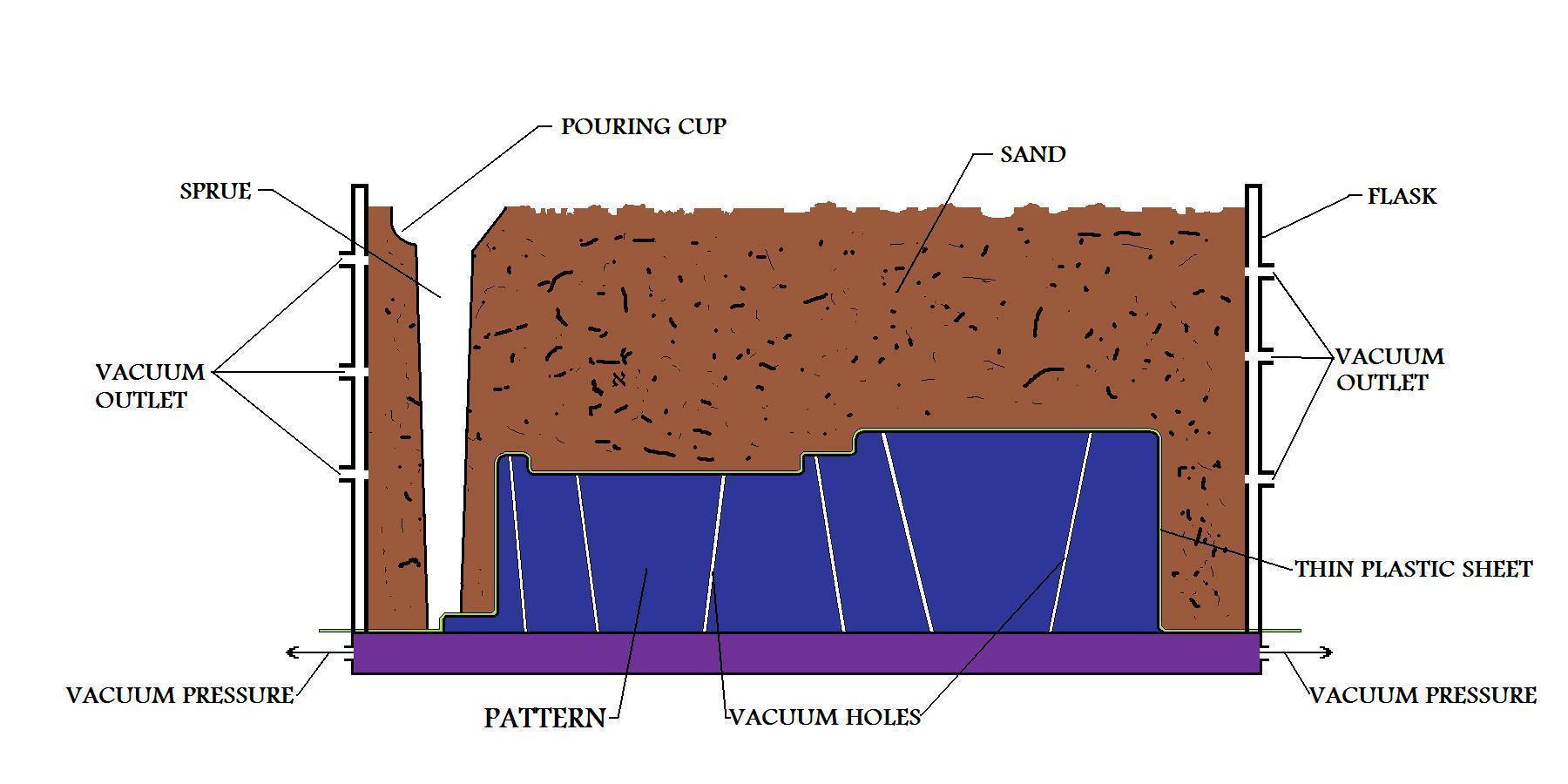

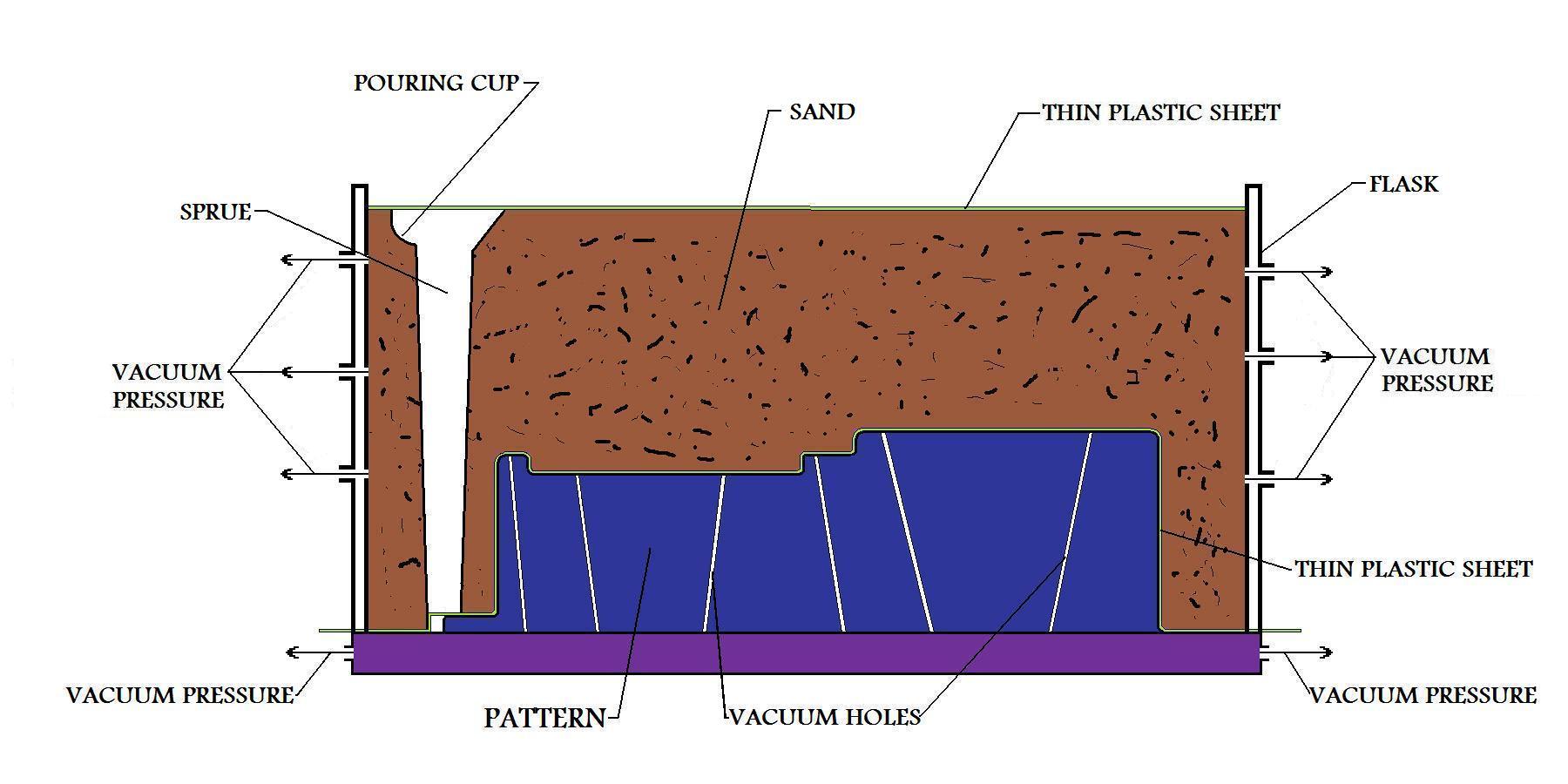

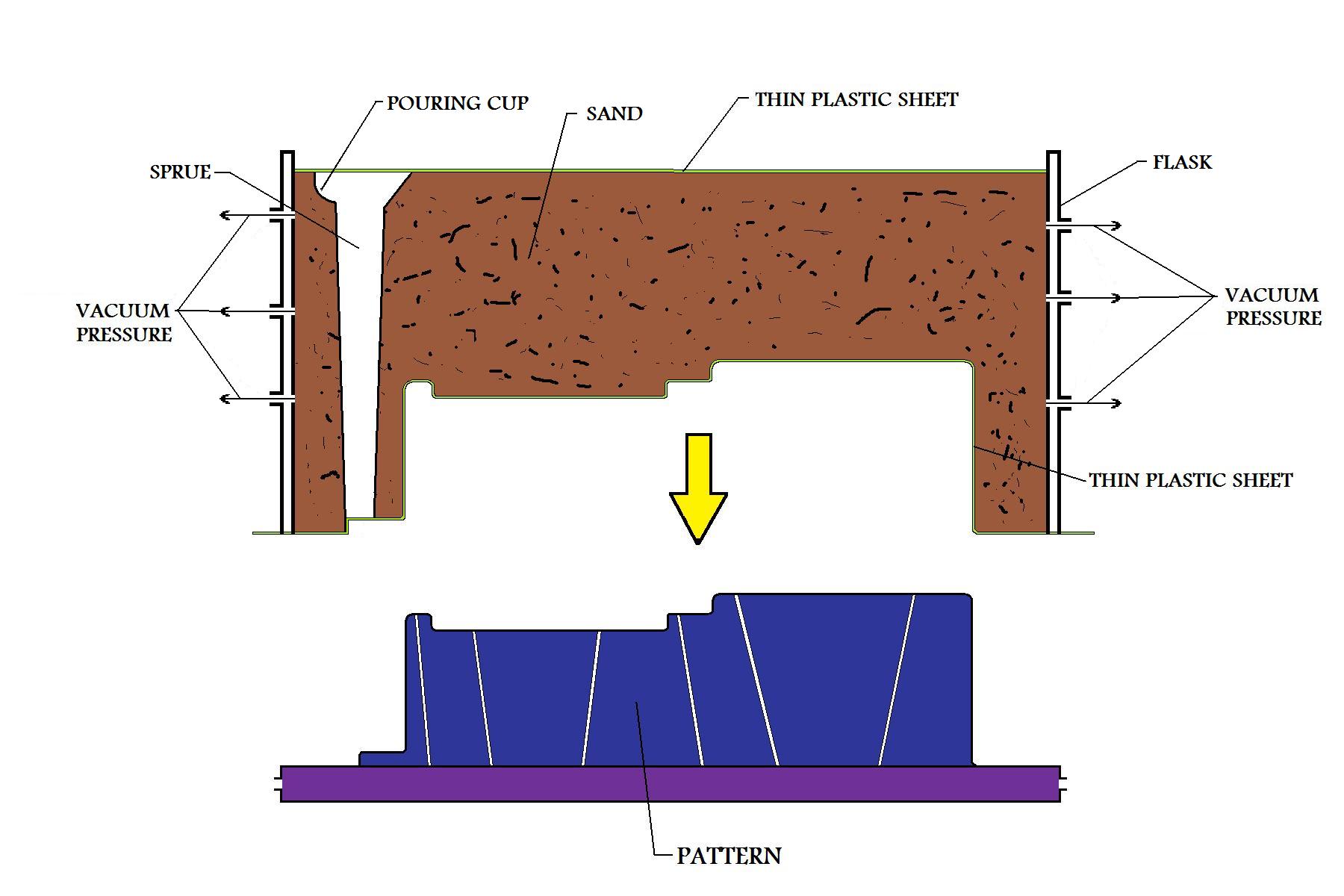

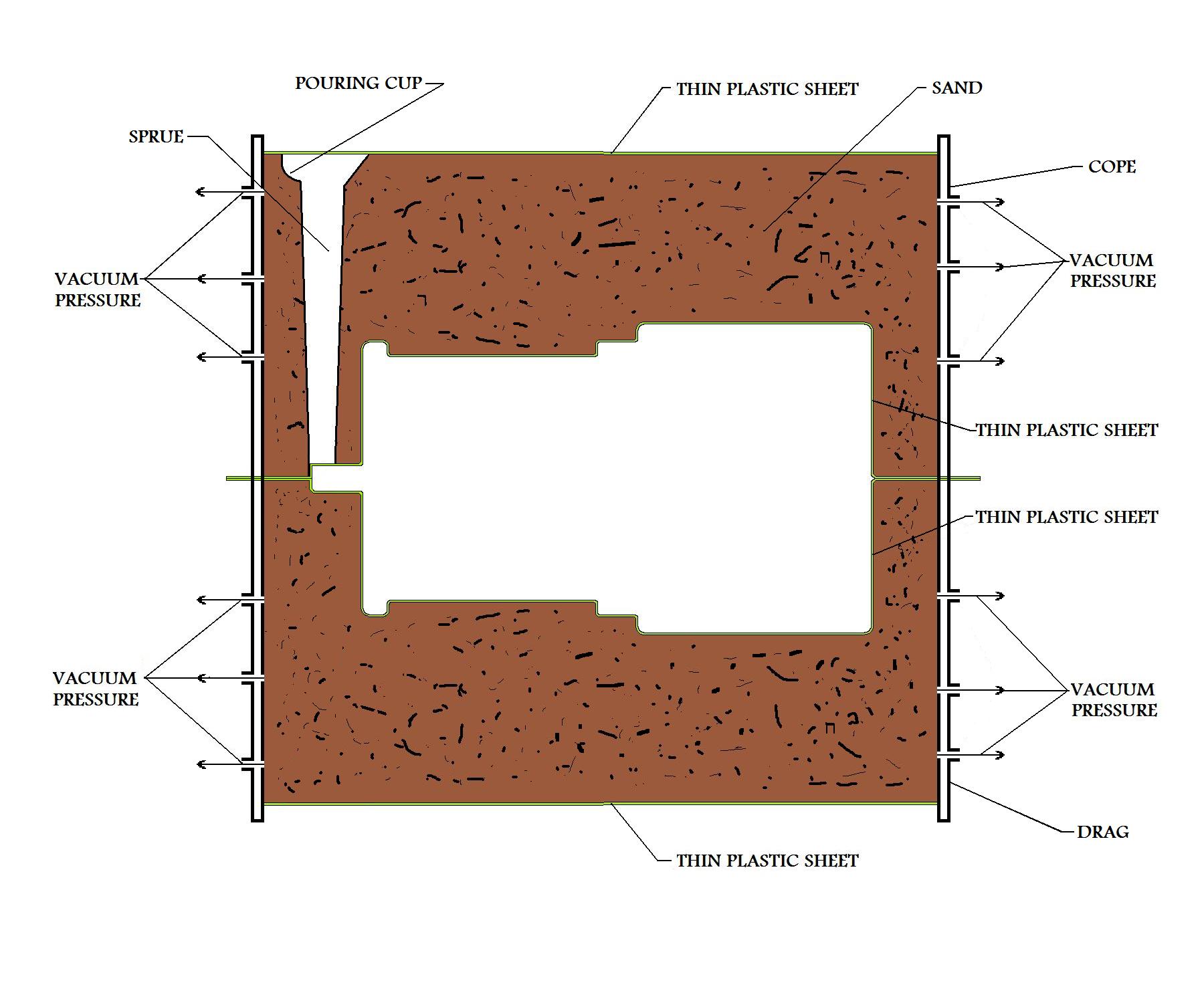

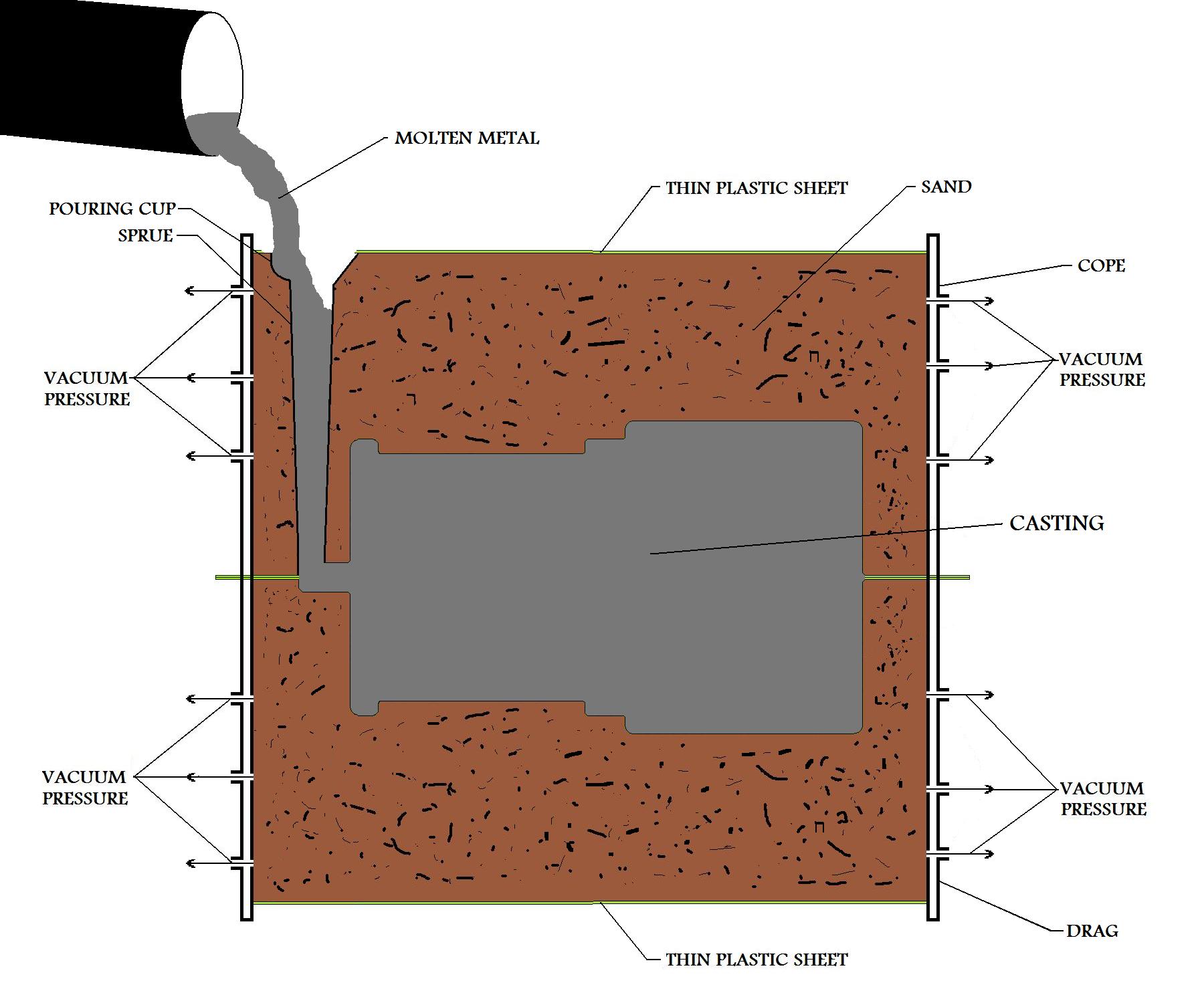

Vacuum

Casting,

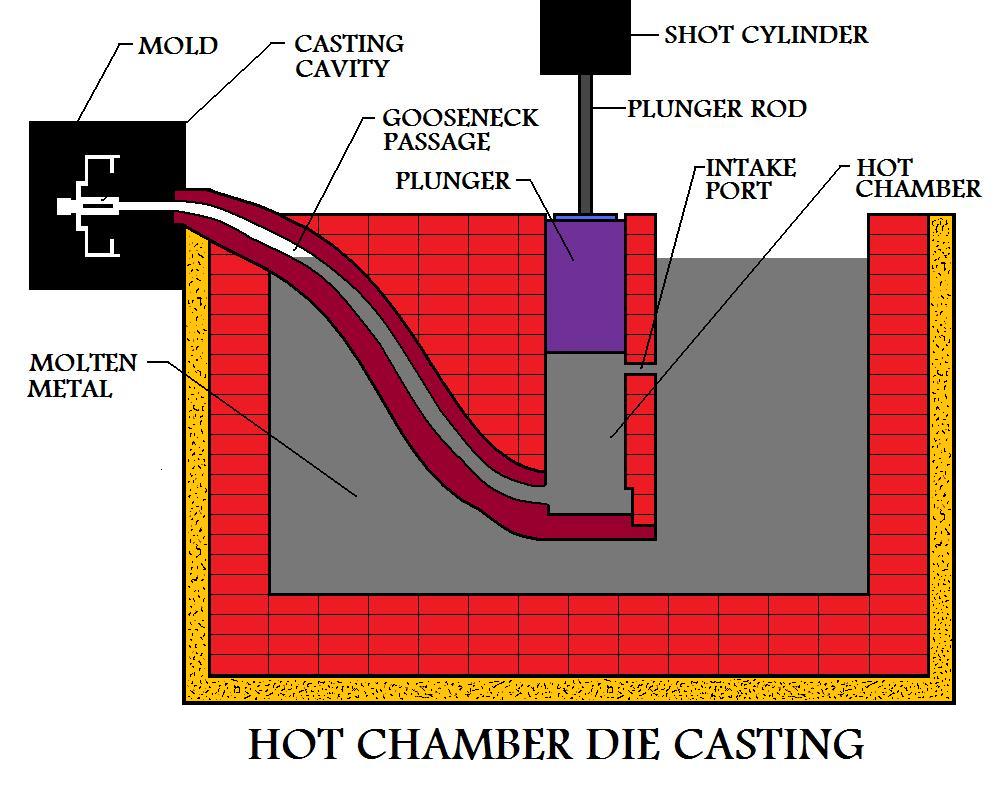

Hot

Chamber Die Casting,