1.

What is flywheel?

A flywheel

is a heavy body rotating about its axis. It acts as a reservoir of energy which

is stored in the form of kinetic energy. The extra energy is stored during the

idle stroke of the driven machinery and released during the working stroke. Thus

flywheel controls the fluctuations of speed during each cycle of the driven

machinery.

2.

What are the functions of flywheel in a

machine?

The

primary function of a flywheel is:

a.

To absorb

energy when demand of energy id less than the supply

b.

To give

out energy when demand of energy is more than the supply.

3.

What types of stresses are set up in the

flywheel rims?

a.

Tensile

stress due to the centrifugal force

b.

Tensile

bending stress due to restraint of the arms

c.

Shrinkage

stresses due to the unequal rate of cooling of casting.

4.

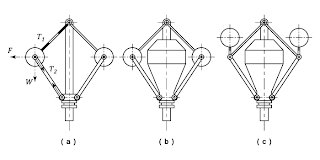

What are the various types of flywheel?

a.

Solid disc

type

b.

Rimmed

type with either arms or solid web

Solid disc type flywheel is rarely used

because they have less capacity of storing energy.

Rimmed type flywheels with arms are preferred

because they can store more energy. Small rimmed type flywheels are

manufactured with solid web or holes drilled in the web.

5.

Why flywheels are used in punching machines?

Use

of flywheel in punching machine is due to the following reasons:

a.

It decreases

the variation of speed during each cycle of punching machine.

b.

It decreases

the fluctuation of speed due to difference in output and input

c.

It stores

energy during idle stroke and releases during working stroke.

6.

Why flywheel is used in IC engines?

In

IC engine or stem engine the energy is developed during the power stroke, no energy

is developed during suction, compression and exhaust strokes in 4 stroke

engine. It helps the crank shaft to run at uniform speed by performing its

primary function

7.

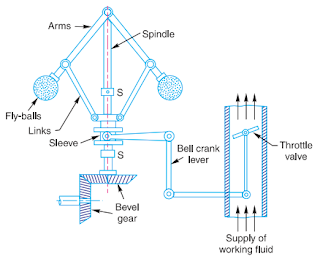

What is the difference in the function of governor

and a flywheel?

Governor

regulates the mean speed of an engine when there are variations in load by

changing the supply of working fluid. Flywheel does not maintain a constant

speed. It reduces the fluctuations.

8.

Coefficient of fluctuation of speed is

------------ of maximum fluctuation of speed and the mean speed

Ratio

9.

Due to centrifugal forces acting on the rim,

the flywheel arms will be subjected to ------------- stresses

Tensile

10. Why

flywheel arm are usually elliptical?

This

shape helps in more section modulus for the dame weight. This results in more

strength than circular section

11. Under

what consideration the shaft for a flywheel is designed?

It

is designed under shear stresses produced due to the combined action of torsion

and bending moment.

12. In a flywheel, the major axis of the

elliptical section of the arm is the plane of rotation. Write done the reason

for this arrangement.

The

arms may have to carry the full torque load due to high inertia of the flywheel

when the energy input to its shaft is cut off. The arm may be assumed as a cantilever

fixed at the hub and carrying the load at the rim end. This bending moment lies

in the plane of rotation of the flywheel. Therefore, the major axis of the arms

must be parallel to the tangential force F acting on the flywheel.

Bending

moment on the arm, M = F(R-dh/2)

F

= t/(nR)

Where

n = number of arms

Section

modulus of arm, Z = (π/32 )b1a12

Bending

stress σb = M/Z

13. On what basis the material of flywheel is selected?

a. High

tensile strength

b. High fatigue strength

c. Low shrinkage

14. What

are the advantages of having elliptical section of flywheel arm?

The

flywheel arms are made of elliptical with major axis twice the minor axis. The major

axis lies in the plane of rotation and provides double the resistance against

bending moment.

15. Difference between flywheel and governor

The function of a governor in engine is

entirely different from that of a flywheel. It regulates the mean speed of an

engine when there are variations in the load, e.g. when the load on the engine increases, it becomes necessary

to increase the supply of working fluid. On the other hand, when the load

decreases, less working fluid is required. The governor automatically controls

the supply of working fluid to the engine with the varying load condition and

keeps the mean speed within certain limits.

As discussed above, the flywheel does not

maintain a constant speed; it simply reduces the fluctuation of speed. In other

words, a flywheel controls the speed variations caused by the fluctuation of

the engine turning moment during each cycle of operation. It does not control

the speed variations caused by the varying load.

16. Define the

following terms

Coefficient of Fluctuation of Speed, coefficient of

steadiness, fluctuation of energy, maximum fluctuation of energy, Coefficient

of Fluctuation of Energy

Coefficient of

fluctuation of speed: The difference between the maximum and

minimum speeds during a cycle is called the maximum fluctuation of speed. The ratio of the maximum

fluctuation of speed to the mean speed is called coefficient of fluctuation of speed.

Coefficient of steadiness: The reciprocal of coefficient of fluctuation of speed is

known as coefficient of steadiness and it is denoted by m.

Fluctuation

of energy, maximum fluctuation of energy:

The

fluctuation of energy may be determined by the turning moment diagram for one

complete cycle of operation. Consider a turning moment diagram for a single

cylinder double acting steam engine as shown in Fig. The vertical ordinate represents the turning

moment and the horizontal ordinate (abscissa) represents the crank angle.

A

little consideration will show that the turning moment is zero when the

crank

angle is zero. It rises to a maximum value when crank angle reaches 90º

and it is

again zero when crank angle is 180º. This is shown by the curve abc in

Fig. and it represents the

turning moment diagram for outstroke. The curve cde is the turning

moment diagram for instroke and is somewhat

similar to the curve abc. Since

the work done is the product of the turning moment and the angle turned,

therefore the area of the turning moment diagram represents the work

done per

revolution. In actual practice, the engine is assumed to work against

the mean

resisting torque, as shown by a horizontal line AF. The height of the

ordinate aA represents the mean height of the turning moment diagram.

Since it is assumed that the work done by the turning moment per

revolution is

equal to the work done against the mean resisting torque, therefore the

area of

the rectangle aA Fe is

proportional to the work done against the mean resisting torque. We see

in Fig.

that the mean resisting torque line AF cuts the turning moment diagram

at

points B, C, D and E. When

the crank moves from ‘a’ to ‘p’ the work done by the engine is

equal to the area aBp, whereas

the energy required is represented by the area aABp. In other words, the

engine has done less work (equal to

the area aAB) than the

requirement. This amount of energy is taken fromthe flywheel and hence

the

speed of the flywheel decreases. Now the crank moves from p to q, the

work done by the engine is equal to the area pBbCq, whereas the

requirement of

energy is represented by the area pBCq.

Therefore the engine has done more work than the requirement. This

excess work (equal

to the area BbC) is stored in

the flywheel and hence the speed of the flywheel increases while the

crank

moves from p to q.

Similarly

when

the crank moves from q to r, more work is taken from the engine

than is developed. This loss of work is represented by the area CcD. To

supply this loss, the

flywheel gives up some of its energy and thus the speed decreases while

the

crank moves from q to r. As the crank moves from r to s, excess energy

is again developed given by the area DdE and the speed again increases.

As

the piston moves from s to e, again there is a loss of work and

the speed decreases. The variations of energy above and below the mean

resisting torque line are called fluctuation

of energy. The areas BbC,

CcD, DdE etc. represent fluctuations of energy. A little

consideration will show that the engine has a maximum speed either at q

or at s. This is due to the fact that the flywheel absorbs energy

while the crank moves from p to

q and from r to s. On the other hand, the engine has a minimum speed

either at p or at r. The reason is that the flywheel gives out some of

its energy when

the crank moves from a to p and from q to r. The difference

between the maximum and the minimum energies is known as maximum fluctuation of energy

Coefficient of Fluctuation of Energy

It is defined as the ratio of the maximum

fluctuation of energy to the work done per cycle. It is usually denoted by CE