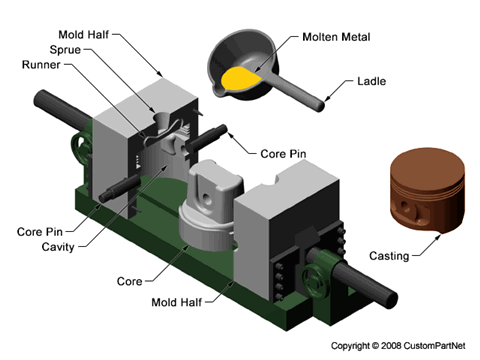

The process is suitable for components with relatively thick wall sections with high mechanical properties, as for example required of safety components in automotive engineering. The cast components can be welded and heattreated, and they can be produced with near net shape. Aluminum alloys can be used which are difficult or impossible to produce by standard die casting.

Buhler selectively utilizes the advantages of the horizontal shot sleeve system.

Advantages using Buhler machines

• The velocity and pressure intensification profile matched to the component geometry can be programmed in very many discrete steps. Real time control maintains these parameters constant.

• Depending on the type of shot unit selected, it is possible to generate high pressure intensification values during the solidification phase.

Your benefits

• Low capital investment, as no special-purpose machines are required.

• Entering of future-oriented market segments using existing SC machines.

• Low maintenance and training requirements thanks to unified machine and die ranges.

Buhler selectively utilizes the advantages of the horizontal shot sleeve system.

Advantages using Buhler machines

• The velocity and pressure intensification profile matched to the component geometry can be programmed in very many discrete steps. Real time control maintains these parameters constant.

• Depending on the type of shot unit selected, it is possible to generate high pressure intensification values during the solidification phase.

Your benefits

• Low capital investment, as no special-purpose machines are required.

• Entering of future-oriented market segments using existing SC machines.

• Low maintenance and training requirements thanks to unified machine and die ranges.