Advantages and disadvantages of shell molding casting

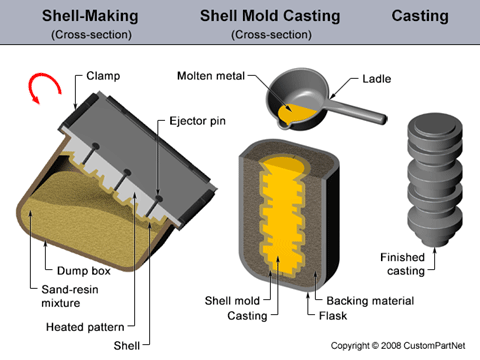

Shell molding casting is a main

sand casting production process. The castings have good surface smoothness, less

surface defects, and good dimensional accuracy. Our foundry has used

this process for many years.

The followings are the advantages of shell molding castings:

1. Good surface quality

Because shell molding uses phenolic resin as the sand binder, so the smooth and hard surfaces of sand molds make the castings have good surface smoothness. The following photo could be taken as sample for the surface quality.

The followings are the advantages of shell molding castings:

1. Good surface quality

Because shell molding uses phenolic resin as the sand binder, so the smooth and hard surfaces of sand molds make the castings have good surface smoothness. The following photo could be taken as sample for the surface quality.

Moreover, this process have less sand

residue during production, so could reduce some

iron casting defects,

such as sand inclusion, sand holes and air holes.

2. High rough casting dimensional accuracy

This molding material is a type of hard mold, so there will be less swell of sand molds, so the dimensional tolerance will be smaller. This advantage will be very useful for producing high accuracy rough castings, and reduce machining cost.

2. High rough casting dimensional accuracy

This molding material is a type of hard mold, so there will be less swell of sand molds, so the dimensional tolerance will be smaller. This advantage will be very useful for producing high accuracy rough castings, and reduce machining cost.

3. Thin wall thickness and complex

castings

Less than 5mm wall thickness will be taken as very thin as for sand castings. Only shell molding process could produce these cast products.

In addition, hot shell and core molds are made by molding machines, so it could produce the castings with complex structures, especially complex inside structures.

4. Less manpower and molding skill requirements

Since the main works have been completed by the molding machines, so this process could be operated by women workers, and there is no special skill required. This is very different with green sand casting process.

Less than 5mm wall thickness will be taken as very thin as for sand castings. Only shell molding process could produce these cast products.

In addition, hot shell and core molds are made by molding machines, so it could produce the castings with complex structures, especially complex inside structures.

4. Less manpower and molding skill requirements

Since the main works have been completed by the molding machines, so this process could be operated by women workers, and there is no special skill required. This is very different with green sand casting process.

The followings are the disadvantages of

this process.

1. High production costs and casting prices

1. High production costs and casting prices

The phenolic resin sand is more

expensive than green sand and furan resin sand, and it could not be

recyclable. Therefore, shell molding castings will have higher

prices.

2. High pattern costs

This process needs to use metal patterns (iron patterns), which will be more costly. So, it is not suitable for producing small quantity castings and small orders.

3. Size and weight limitation

The shells and cores of castings are produced by shell molding machines. These machines have dimensional limitation. So, most of shell molding castings will be less than 400mm length, and less than 20kg weight. Too long or too heavy can not be produced by this process.

Although shell and core molding process has these disadvantages, but its advantages are also very important. So, more and more iron foundries in China are using it to produce small and middle iron castings. As we know, in other countries, many metal foundries are using it to produce steel castings to replace lost wax casting process.

2. High pattern costs

This process needs to use metal patterns (iron patterns), which will be more costly. So, it is not suitable for producing small quantity castings and small orders.

3. Size and weight limitation

The shells and cores of castings are produced by shell molding machines. These machines have dimensional limitation. So, most of shell molding castings will be less than 400mm length, and less than 20kg weight. Too long or too heavy can not be produced by this process.

Although shell and core molding process has these disadvantages, but its advantages are also very important. So, more and more iron foundries in China are using it to produce small and middle iron castings. As we know, in other countries, many metal foundries are using it to produce steel castings to replace lost wax casting process.