Plaster mold casting is a manufacturing process having a similar technique to sand casting.

Plaster of Paris is used to form the mold for the casting, instead of sand. In industry parts such as valves, tooling,

gears, and lock components may be manufactured by plaster mold casting.

The Process

Initially plaster of Paris is mixed with water just like in the first step of the formation of any plaster part. In the next step of the manufacture of a plaster casting mold, the plaster of Paris and water are then mixed with various additives such as talc and silica flour. The additives serve to control the setting time of the plaster and improve its strength. The plaster of Paris mixture is then poured over the casting pattern. The slurry must sit for about 20 minutes before it sets enough to remove the pattern. The pattern used for this type of metal casting manufacture should be made from plastic or metal. Since it will experience prolonged exposure to water from the plaster mix, wood casting patterns have a tendency to warp. After striping the pattern, the mold must be baked for several hours, to remove the moisture and become hard enough to pour the metal casting. The two halves of the mold are then assembled for the casting process.Properties and Considerations of Manufacturing by Plaster Mold Casting

- When baking the casting mold just the right amount of water should be left in the mold material. Too

much moisture in the mold can cause metal casting defects, but if the mold is too dehydrated, it will lack

adequate strength.

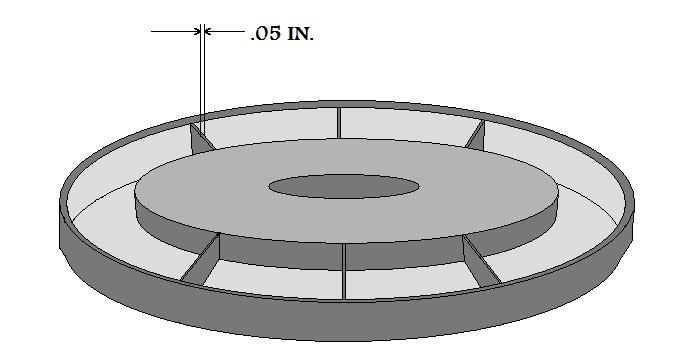

- The fluid plaster slurry flows readily over the pattern, making an impression of great detail and

surface finish. Also due to the low thermal conductivity of the mold material the casting will

solidify slowly creating more uniform grain structure and mitigating casting warping. The qualities of

the plaster mold enable the process to manufacture parts with excellent surface finish, thin sections,

and produces high geometric accuracy.

Castings of high detail and section thickness as low as .04 - .1 inch, (2.5 - 1 mm), are possible when manufacturing by plaster mold casting |

- There is a limit to the casting materials that may be used for this type of manufacturing process, due

to the fact that a plaster mold will not withstand temperature above 2200F (1200C). Higher melting point

metals can not be cast in plaster. This process is typically used in industry to manufacture castings made

from aluminum, magnesium, zinc, and copper based alloys.

- Manufacturing production rates for this type of metal casting process are relatively slow, due to the

long preparation time of the mold.

- The plaster mold is not permeable, which severely limits the escape of gases from the casting.

Other Topics

IC engine,

Air

Standard Cycles, Method

of Ignition, Gear Types,

mechanical

Engineering, Gears, spur gears,Worm gears,English books,Photoshop

tutorials,Physics files,Thamizh,Manufacturing,Gears pdf,Computer

science,Harry

potter,Best

100 english books,Face Gears,IC

engine,Metal

Casting,Sand

casting,SAND

Casting Quiz,Casting

patterns quiz,Sand

Casting Process,Patterns,Mechnical

Previous Years Gate Question Papers ,Mechanical-old-question-paper,Core

and Core Box,Shell

Moulding,Permanent

mold casting,Investment

Casting,Die

Casting,Centrifugal

Casting,Workshop

Technology Quiz,Milling

Quiz,Metal

Quiz,Mechanical

Process Quiz,Chemically

Bonded Molding Systems,Unbonded

Sand Processes,Green

Sand Molding,Gases

Iin Metal Casting,

No comments:

Post a Comment