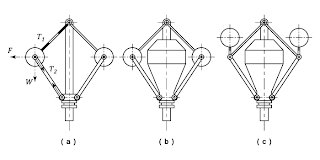

This works on a different principle. The governor balls are arranged so that the inertia forces caused by angular acceleration or retardation of the governor shaft tend to alter their positions. The amount of the displacement of the balls is controlled by springs and

the governor mechanism to alter the supply of energ y to the engine.

The advantage of this type of governor is that the positions of the balls are affected by

the rate of change of speed of the governor shaft.Consequently, a more rapid response

to a change of load is obtained, since the action of the governor is due to acceleration

and not to a finite change of speed. The advantageis offset, however, by the practical

difficulty of arranging for a complete balance of the revolving parts of the governor. For

this reason centrifugal governors are much more frequently used.

Other Topics

IC engine, Method

of Ignition, mechanical

Engineering, English books,Photoshop

tutorials,Harry

potter,Best

100 english books,IC

engine,Metal

Casting,Mechnical

Previous Years Gate Question Papers ,Mechanical-old-question-paper,Milling

Quiz,Forging

Quiz,Cold

Extrusion,Hot

Extrusion,CLutch,Dry Clutch,Wet Clutch,Introduction

to Flywheel,Flywheel

Benefits,FlyWheel:

Energy,FlyWheel:

Moment of Inertia,FlyWheel:Rotational

Speed,Important

questions and answers on Design of Flywheel,Flywheel:

FACTOR,

Governors ,Types

of Governors,Cenrifugal

Governors

No comments:

Post a Comment