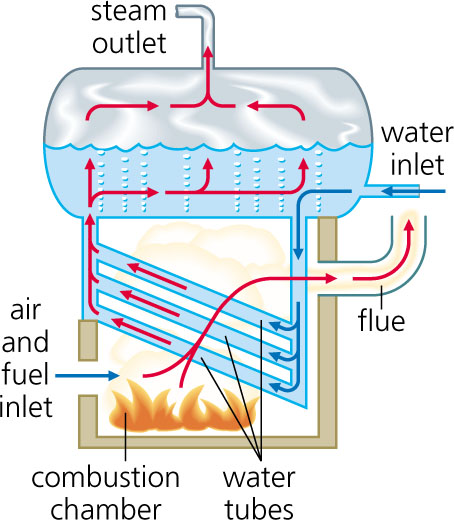

Water Tube Boiler

In water tube boiler,

boiler feed water flows through the tubes and enters the boiler drum.

The circulated water is heated by the combustion gases and converted

into steam at the vapour space in the drum. These boilers are selected

when the steam demand as well as steam pressure requirements are high as

in the case of process cum power boiler / power boilers.

Most modern water boiler

tube designs are within the capacity range 4,500 – 120,000 kg/hour of

steam, at very high pressures. Many water tube boilers nowadays are of

“packaged” construction if oil and /or gas are to be used as fuel. Solid

fuel fired water tube designs are available but packaged designs are

less common.

The features of water tube boilers are:

- Forced, induced and balanced draft provisions help to improve combustion efficiency.

- Less tolerance for water quality calls for water treatment plant.

- Higher thermal efficiency levels are possible

Other Topics

IC engine, Method

of Ignition, mechanical

Engineering, English books,Photoshop

tutorials,Harry

potter,Best

100 english books,IC

engine,Metal

Casting,Mechnical

Previous Years Gate Question Papers ,Mechanical-old-question-paper,Milling

Quiz,Forging

Quiz,Cold

Extrusion,Hot

Extrusion,CLutch,Wet Clutch,Introduction

to Flywheel,Flywheel:

FACTOR,

Governors ,Thermal

Power Plant,Pulverizer,Boiler,What

type of boiler do you need?,Fluidized

Bed Combustion (FBC) Boiler,Fire

Tube Boiler,Water

Tube Boiler

No comments:

Post a Comment