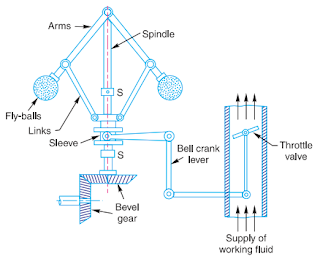

A governor is said to be stable when for every speed within the working range there is a definite configuration i.e. there is only one radius of rotation of the governor balls at which the governor is in equilibrium.

For a stable governor, if the equilibrium speed increases, the radius of governor balls must also increase.

Other Topics

IC engine, Method

of Ignition, mechanical

Engineering, English books,Photoshop

tutorials,Harry

potter,Best

100 english books,IC

engine,Metal

Casting,Mechnical

Previous Years Gate Question Papers ,Mechanical-old-question-paper,Milling

Quiz,Forging

Quiz,Cold

Extrusion,Hot

Extrusion,CLutch,Dry Clutch,Wet Clutch,Introduction

to Flywheel,Flywheel

Benefits,FlyWheel:

Energy,FlyWheel:

Moment of Inertia,FlyWheel:Rotational

Speed,Important

questions and answers on Design of Flywheel,Flywheel:

FACTOR,

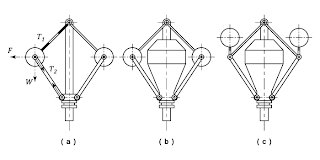

Governors ,Types

of Governors,Cenrifugal

Governors,Inertia

Governors