TYPED BY METHOD OF HEAT TRANSFER

All

of the cooling towers described here are evaporative type towers, in

that they derive their primary cooling effect from the evaporation that

takes place when air and water are brought into the direct contact. At

the other end os the spectrum is the Dry tower, where by full

utilization of dry surface coil sections, no direct contact (and no

evaporation) occurs between air and water. Hence sensible heat transfer

cools the water totally.

IN between these extremes are the plume abatement and water conservation towers, wherein progressively greater portions of dry surface coil sections are introduced into the overall heat transfer system to alleviate specific problems or to accomplish specific requirements

IN between these extremes are the plume abatement and water conservation towers, wherein progressively greater portions of dry surface coil sections are introduced into the overall heat transfer system to alleviate specific problems or to accomplish specific requirements

Other Topics

IC engine, Method

of Ignition, mechanical

Engineering, English books,Photoshop

tutorials,Harry

potter,Best

100 english books,IC

engine,Metal

Casting,Mechnical

Previous Years Gate Question Papers ,Mechanical-old-question-paper,Milling

Quiz,Forging

Quiz,Cold

Extrusion,Hot

Extrusion,CLutch,Wet Clutch,Introduction

to Flywheel,Flywheel:

FACTOR,

Governors ,Thermal

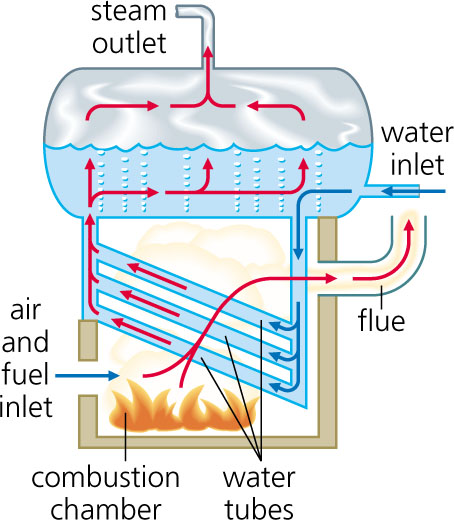

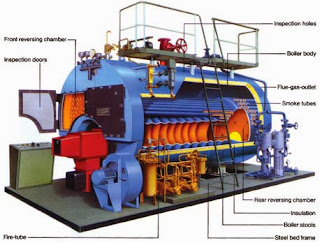

Power Plant,Pulverizer,Boiler,Fire

Tube Boiler,Water

Tube Boiler,Packaged

Boiler,Superheater,Condenser,Types

of Condenser,Air-cooled

condenser types,Water-Cooled

Condensers,Evaporative

Condensers,TYPES

OF COOLING TOWERS,TYPES

OF COOLING TOWERS,Cooling

Tower: ATMOSPHERIC ,Cooling

Tower:MECHANICAL DRAFT ,Cooling

Tower:HYBRID DRAFT ,Cooling

Tower:CHARACTERIZATION BY AIR FLOW,Cooling

Tower:SPRAY – FILLED ,Cooling

Tower:TYPES BY SHAPE,Cooling

Tower:TYPED BY METHOD OF HEAT TRANSFER