Thermal Power Plant Lay out :

The above diagram is the lay out of a simplified thermal power plant and the below is also diagram of a thermal power plant.

The above diagram shows the simplest arrangement of Coal fired (Thermal) power plant.

Main parts of the plant are

1. Coal conveyor

2. Stoker

3. Pulverizer

4. Boiler

5. Coal ash

6. Air preheater

7. Electrostatic precipitator

8. Smoke stack

9. Turbine

10. Condenser

11. Transformers

12. Cooling towers

13. Generator

14. High - votge power lines

Basic Operation :A thermal power plant basically works on

Rankine cycle.

Coal conveyor : This

is a belt type of arrangement.With this coal is transported from coal

storage place in power plant to the place near by boiler.

Stoker : The

coal which is brought near by boiler has to put in boiler furnance for

combustion.This stoker is a mechanical device for feeding coal to a

furnace.

Pulverizer :

The coal is put in the boiler after pulverization.For this pulverizer

is used.A pulverizer is a device for grinding coal for combustion in a

furnace in a power plant.

Types of Pulverizers :

Ball and Tube Mill Ball mill is a

pulverizer that consists of a horizontal rotating cylinder, up to three

diameters in length, containing a charge of tumbling or cascading steel

balls, pebbles, or rods.

Tube mill is a revolving cylinder of up to five diameters in length used

for fine pulverization of ore, rock, and other such materials; the

material, mixed with water, is fed into the chamber from one end, and

passes out the other end as slime.

Ring and Ball

This type consists of two rings separated by a series of large balls.

The lower ring rotates, while the upper ring presses down on the balls

via a set of spring and adjuster assemblies. Coal is introduced into the

center or side of the pulverizer (depending on the design) and is

ground as the lower ring rotates causing the balls to orbit between the

upper and lower rings. The coal is carried out of the mill by the flow

of air moving through it. The size of the coal particals released from

the grinding section of the mill is determined by a classifer separator.

These mills are typically produced by B&W (Babcock and Wilcox).

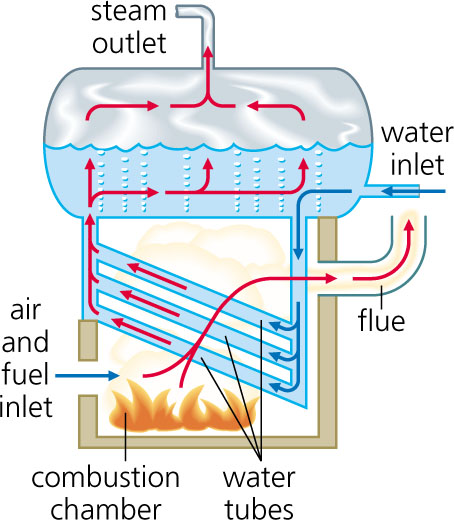

Boiler : Now that pulverized coal is put in boiler furnance.Boiler is an enclosed vessel in which water is heated and circulated until the water is turned in to steam at the required pressure.

Coal is burned inside the combustion chamber of boiler.The products of

combustion are nothing but gases.These gases which are at high

temperature vaporize the water inside the boiler to steam.Some times

this steam is further heated in a superheater as

higher the steam pressure and temperature the greater efficiency the

engine will have in converting the heat in steam in to mechanical work.

This steam at high pressure and tempeture is used directly as a heating

medium, or as the working fluid in a prime mover to convert thermal

energy to mechanical work, which in turn may be converted to electrical

energy. Although other fluids are sometimes used for these purposes,

water is by far the most common because of its economy and suitable

thermodynamic characteristics.

Classification of Boilers

Bolilers are classified as

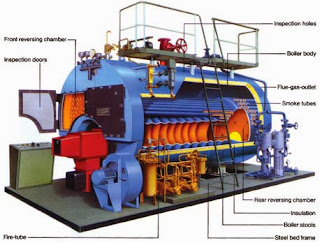

Fire tube boilers :

Fire tube boilers : In

fire tube boilers hot gases are passed through the tubes and water

surrounds these tubes. These are simple,compact and rugged in

construction.Depending on whether the tubes are vertical or horizontal

these are further classified as vertical and horizontal tube boilers.In

this since the water volume is more,circulation will be poor.So they

can't meet quickly the changes in steam demand.High pressures of steam

are not possible,maximum pressure that can be attained is about

17.5kg/sq cm.Due to large quantity of water in the drain it requires

more time for steam raising.The steam attained is generally

wet,economical for low pressures.The outut of the boiler is also

limited.

Water tube boilers : In these boilers water is inside the tubes and hot gases are outside the tubes.They consists of drums and

tubes.They

may contain any number of drums (you can see 2 drums in fig).Feed water

enters the boiler to one drum (here it is drum below the boiler).This

water circulates through the tubes connected external to drums.Hot gases

which surrounds these tubes wil convert the water in tubes in to

steam.This steam is passed through tubes and collected at the top of the

drum since it is of light weight.So the drums store steam and water

(upper drum).The entire steam is collected in one drum and it is taken

out from there (see in laout fig).As the movement of water in the water

tubes is high, so rate of heat transfer also becomes high resulting in

greater efficiency.They produce high pressure , easily accessible and

can respond quickly to changes in steam demand.These are also classified

as vertical,horizontal and inclined tube depending on the arrangement

of the tubes.These are of less weight and less liable to explosion.Large

heating surfaces can be obtained by use of large number of tubes.We can

attain pressure as high as 125 kg/sq cm and temperatures from 315 to

575 centigrade.

tubes.They

may contain any number of drums (you can see 2 drums in fig).Feed water

enters the boiler to one drum (here it is drum below the boiler).This

water circulates through the tubes connected external to drums.Hot gases

which surrounds these tubes wil convert the water in tubes in to

steam.This steam is passed through tubes and collected at the top of the

drum since it is of light weight.So the drums store steam and water

(upper drum).The entire steam is collected in one drum and it is taken

out from there (see in laout fig).As the movement of water in the water

tubes is high, so rate of heat transfer also becomes high resulting in

greater efficiency.They produce high pressure , easily accessible and

can respond quickly to changes in steam demand.These are also classified

as vertical,horizontal and inclined tube depending on the arrangement

of the tubes.These are of less weight and less liable to explosion.Large

heating surfaces can be obtained by use of large number of tubes.We can

attain pressure as high as 125 kg/sq cm and temperatures from 315 to

575 centigrade.

Superheater : Most of the modern boliers are having superheater and reheater arrangement. Superheater is a component

of a steam-generating unit in which steam, after it has left the boiler

drum, is heated above its saturation temperature. The amount of

superheat added to the steam is influenced by the location, arrangement,

and amount of superheater surface installed, as well as the rating of

the boiler. The superheater may consist of one or more stages of tube

banks arranged to effectively transfer heat from the products of

combustion.Superheaters are classified as convection , radiant or

combination of these.

Reheater : Some of the heat of superheated steam is used to rotate the turbine where it loses some of its energy.Reheater is also steam

boiler component in which heat is added to this intermediate-pressure

steam, which has given up some of its energy in expansion through the

high-pressure turbine. The steam after reheating is used to rotate the

second steam turbine (see Layout fig) where the heat is converted to

mechanical energy.This mechanical energy is used to run the alternator,

which is coupled to turbine , there by generating elecrical energy.

Condenser : Steam

after rotating staem turbine comes to condenser.Condenser refers here

to the shell and tube heat exchanger (or surface condenser) installed at

the outlet of every steam turbine in Thermal power stations of utility

companies generally. These condensers are heat exchangers which convert

steam from its gaseous to its liquid state, also known as phase

transition. In so doing, the latent heat of steam is given out inside

the condenser. Where water is in short supply an air cooled condenser is

often used. An air cooled condenser is however significantly more

expensive and cannot achieve as low a steam turbine backpressure (and

therefore less efficient) as a surface condenser.

The purpose is to condense the outlet (or exhaust) steam from steam turbine to obtain maximum efficiencyand

also to get the condensed steam in the form of pure water, otherwise

known as condensate, back to steam generator or (boiler) as boiler feed

water.

Why it is required ?

The steam turbine itself is a device to convert the heat in steam to

mechanical power. The difference between the heat of steam per unit

weight at the inlet to turbine and the heat of steam per unit weight at

the outlet to turbine represents the heat given out (or heat drop) in

the steam turbine which is converted to mechanical power. The heat drop

per unit weight of steam is also measured by the word enthalpy drop.

Therefore the more the conversion of heat per pound (or kilogram) of

steam to mechanical power in the turbine, the better is its performance

or otherwise known as efficiency. By condensing the exhaust steam of

turbine, the exhaust pressure is brought down below atmospheric pressure

from above atmospheric pressure, increasing the steam pressure drop

between inlet and exhaust of steam turbine. This further reduction in

exhaust pressure gives out more heat per unit weight of steam input to

the steam turbine, for conversion to mechanical power. Most of the heat

liberated due to condensing, i.e., latent heat of steam, is carried away

by the cooling medium. (water inside tubes in a surface condenser, or

droplets in a spray condenser (Heller system) or air around tubes in an

air-cooled condenser).

Condensers are

classified as (i) Jet condensers or contact condensers (ii) Surface condensers.

In jet condensers the

steam to be condensed mixes with the cooling water and the temperature

of the condensate and the cooling water is same when leaving the

condenser; and the condensate can't be recovered for use as feed water

to the boiler; heat transfer is by direct conduction.

In surface condensers there

is no direct contact between the steam to be condensed and the

circulating cooling water. There is a wall interposed between them

through heat must be convectively transferred.The temperature of the

condensate may be higher than the temperature of the cooling water at

outlet and the condnsate is recovered as feed water to the boiler.Both

the cooling water and the condensate are separetely with drawn.Because

of this advantage surface condensers are used in thermal power

plants.Final output of condenser is water at low temperature is passed

to high pressure feed water heater,it is heated and again passed as feed

water to the boiler.Since we are passing water at high temperature as

feed water the temperature inside the boiler does not dcrease and boiler

efficincy also maintained.

Cooling Towers :The

condensate (water) formed in the condeser after condensation is

initially at high temperature.This hot water is passed to cooling

towers.It is a tower- or

building-like device in which atmospheric air (the heat receiver)

circulates in direct or indirect contact with warmer water (the heat

source) and the water is thereby cooled (see illustration). A cooling

tower may serve as the heat sink in a conventional thermodynamic

process, such as refrigeration or steam power generation, and when it is

convenient or desirable to make final heat rejection to atmospheric

air. Water, acting as the heat-transfer fluid, gives up heat to

atmospheric air, and thus cooled, is recirculated through the system, affording economical operation of the process.

Two basic types of cooling towers are commonly used. One transfers the

heat from warmer water to cooler air mainly by an evaporation

heat-transfer process and is known as the

evaporative or wet cooling tower.

Evaporative cooling towers are classified according to the means employed for producing air circulation through them:atmospheric, natural draft, and mechanical draft.

The other transfers the heat from warmer water to cooler air by a

sensible heat-transfer process and is known as the nonevaporative or dry

cooling tower.

Nonevaporative cooling towers are classified as air-cooled condensers

and as air-cooled heat exchangers, and are further classified by the

means used for producing air circulation through them. These two basic

types are sometimes combined, with the two cooling processes generally

used in parallel or separately, and are then known as

wet-dry cooling towers.

Evaluation of cooling tower performance is based on cooling of a

specified quantity of water through a given range and to a specified

temperature approach to the wet-bulb or dry-bulb temperature for which

the tower is designed. Because exact design conditions are rarely

experienced in operation, estimated performance curves are frequently

prepared for a specific installation, and provide a means for comparing

the measured performance with design conditions.

Economiser : Flue

gases coming out of the boiler carry lot of heat.Function of economiser

is to recover some of the heat from the heat carried away in the flue

gases up the chimney and utilize for heating the feed water to the

boiler.It is placed in the passage of flue gases in between the exit

from the boiler and the entry to the chimney.The use of economiser

results in saving in coal consumption , increase in steaming rate and

high boiler efficiency but needs extra investment and increase in

maintenance costs and floor area required for the plant.This is used in

all modern plants.In this a large number of small diameter thin walled

tubes are placed between two headers.Feed water enters the tube through

one header and leaves through the other.The flue gases flow out side the

tubes usually in counter flow.

Air preheater : The remaining heat of flue gases is utilised by air preheater.It is a device

used in steam boilers to transfer heat from the flue gases to the

combustion air before the air enters the furnace. Also known as air

heater; air-heating system. It is not shown in the lay out.But it is

kept at a place near by where the air enters in to the boiler.

The purpose of the air preheater is to

recover the heat from the flue gas from the boiler to improve boiler

efficiency by burning warm air which increases combustion efficiency,

and reducing useful heat lost from the flue. As a consequence, the gases

are also sent to the chimney or stack at a lower temperature, allowing

simplified design of the ducting and stack. It also allows control over

the temperature of gases leaving the stack (to meet emissions

regulations, for example).After extracting heat flue gases are passed to

elctrostatic precipitator.

Electrostatic precipitator : It

is a device which removes dust or other finely divided particles from

flue gases by charging the particles inductively with an electric field,

then attracting them to highly charged collector plates. Also known as

precipitator. The process depends on two steps. In the first step the

suspension passes through an electric discharge (corona discharge) area

where ionization of the gas occurs. The ions produced collide with the

suspended particles and confer on them an electric charge. The charged

particles drift toward an electrode of opposite sign and are deposited

on the electrode where their electric charge is neutralized. The

phenomenon would be more correctly designated as electrodeposition from

the gas phase.

The use of electrostatic precipitators has

become common in numerous industrial applications. Among the advantages

of the electrostatic precipitator are its ability to handle large

volumes of gas, at elevated temperatures if necessary, with a reasonably

small pressure drop, and the removal of particles in the micrometer

range. Some of the usual applications are: (1) removal of dirt from flue

gases in steam plants; (2) cleaning of air to remove fungi and bacteria

in establishments producing antibiotics and other drugs, and in

operating rooms; (3) cleaning of air in ventilation and air conditioning

systems; (4) removal of oil mists in machine shops and acid mists in

chemical process plants; (5) cleaning of blast furnace gases; (6)

recovery of valuable materials such as oxides of copper, lead, and tin;

and (7) separation of rutile from zirconium sand.