Types of Hydropower Plants

There are three types of hydropower facilities: impoundment, diversion, and pumped storage. Some hydropower plants use dams and some do not. The images below show both types of hydropower plants.Many dams were built for other purposes and hydropower was added later. In the United States, there are about 80,000 dams of which only 2,400 produce power. The other dams are for recreation, stock/farm ponds, flood control, water supply, and irrigation.

Hydropower plants range in size from small systems for a home or village to large projects producing electricity for utilities. The sizes of hydropower plants are described below.

Impoundment

The most common type of hydroelectric power plant is an impoundment facility. An impoundment facility, typically a large hydropower system, uses a dam to store river water in a reservoir. Water released from the reservoir flows through a turbine, spinning it, which in turn activates a generator to produce electricity. The water may be released either to meet changing electricity needs or to maintain a constant reservoir level.

An impoundment hydropower plant dams water in a reservoir.

Diversion

A diversion, sometimes called run-of-river, facility channels a portion of a river through a canal or penstock. It may not require the use of a dam.

The Tazimina project in Alaska is an example of a diversion hydropower plant. No dam was required.

Pumped Storage

When the demand for electricity is low, a pumped storage facility stores energy by pumping water from a lower reservoir to an upper reservoir. During periods of high electrical demand, the water is released back to the lower reservoir to generate electricity.Sizes of Hydroelectric Power Plants

Facilities range in size from large power plants that supply many consumers with electricity to small and micro plants that individuals operate for their own energy needs or to sell power to utilities.Large Hydropower

Although definitions vary, DOE defines large hydropower as facilities that have a capacity of more than 30 megawatts.Small Hydropower

Although definitions vary, DOE defines small hydropower as facilities that have a capacity of 100 kilowatts to 30 megawatts.Micro Hydropower

A micro hydropower plant has a capacity of up to 100 kilowatts. A small or micro-hydroelectric power system can produce enough electricity for a home, farm, ranch, or village. .

.

Other Topics

IC engine, Method

of Ignition, mechanical

Engineering, English books,Photoshop

tutorials,Harry

potter,Best

100 english books,IC

engine,Metal

Casting,Mechnical

Previous Years Gate Question Papers ,Mechanical-old-question-paper,Milling

Quiz,Forging

Quiz,Cold

Extrusion,Hot

Extrusion,CLutch,Wet Clutch,Introduction

to Flywheel,Flywheel:

FACTOR,

Governors ,Thermal

Power Plant,Pulverizer,Boiler,Fire

Tube Boiler,Water

Tube Boiler,Packaged

Boiler,Superheater,Condenser,Types

of Condenser,Air-cooled

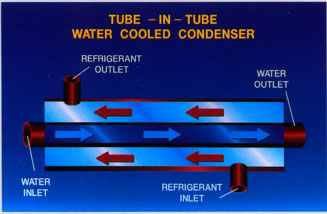

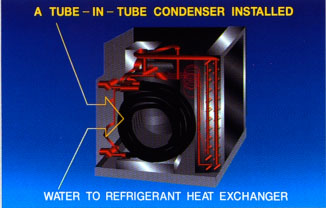

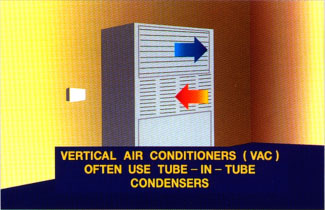

condenser types,Water-Cooled

Condensers,Evaporative

Condensers,TYPES

OF COOLING TOWERS,Hydroelectric

Power Plants